System background:

The existence of any mechanical faults and defects in the power equipment may affect the overall performance and safety of the equipment, and even cause the blackout in the local area and even the whole area. Due to the structural reasons of some power equipment, a large amount of manpower and material resources should be invested when the power outages are overhauled and a long time of maintenance is consumed, resulting in great influence and loss. Therefore, it is particularly important to detect and determine the location, nature and degree of internal defects before the failure of power equipment.

System function:

The mechanical structure defects inside the equipment can be found without interruption or interruption. Through the multi-directional X ray imaging of the power equipment, with the special image processing and recognition technology, the "visualization" and the rapid diagnosis of the running state of the internal structure can be realized, and the fault location and accuracy of the equipment can be greatly improved.

Technical principles:

With the attenuation characteristic of X ray propagation in the medium, when the X ray with uniform intensity is produced and emitted from the side of the detected equipment, the intensity of the X ray after the inspection equipment will not be uniform and the imaging equipment is detected on the other side. The residual X ray intensity after the inspection of the equipment can determine whether the defects in the surface or inside of the detected equipment are defective, and the type and properties of the defects can be judged according to the generated X ray images.

Application status:

1, the existing X ray inspection products are generic products, not for the development of the power industry, not really used in power production. The cost of the equipment is high and the economy is low.

2. The structure of the tested equipment is complex, the volume and weight of the X ray equipment are large, and it is difficult to locate and locate.

3, the lack of dedicated software, as well as image processing, fault location, intelligent recognition and analysis function for power equipment, data utilization rate is low.

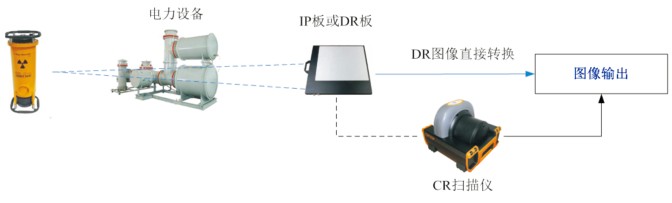

Detection mode:

The new GIS equipment: the pre installation components were screened and tested before the installation was completed, and the defects in the process of manufacturing, transportation and installation were found, and the equipment health files were established.

GIS inspection of substation: find out the defects in the process of operation, compare and analyze the historical data in the equipment health file, understand the deterioration trend of equipment and discover the potential problems.

GIS maintenance in the substation: when the abnormal operating conditions are found in the maintenance process or when other detection means (such as partial discharge detection) can not be identified or located, the diagnostic testing service is provided.

Use the scene:

X ray Digital Imaging Nondestructive testing is widely used in the closed structure of electric power transmission and transmission systems. It includes GIS, pillar insulator, tank type circuit breaker, porcelain column circuit breaker, cable, tension clamp, power cable and so on.

Solution:

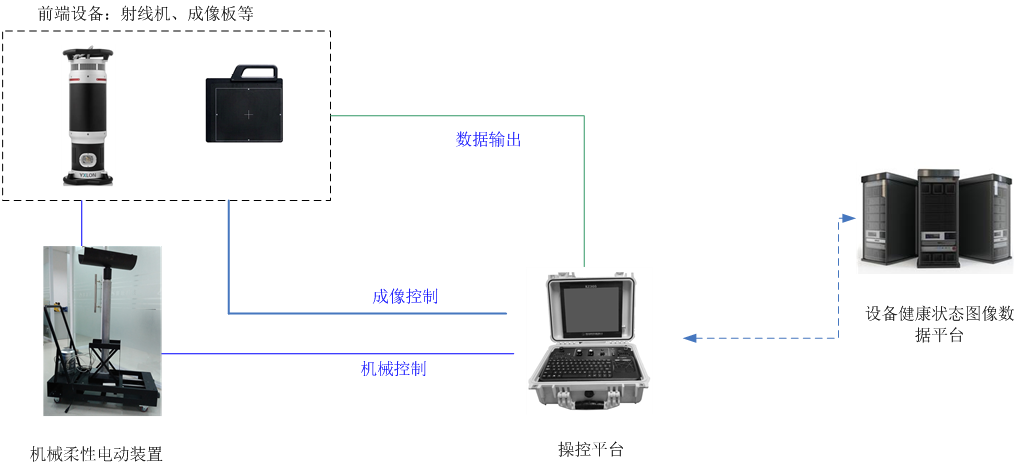

The X ray nondestructive testing system is composed of front-end equipment, mechanical flexible electric device and equipment monitoring status image data platform. According to the detection objects, it is divided into X ray nondestructive testing system and X ray nondestructive testing system for transmission equipment.

The front-end equipment mainly includes radiography machine and digital flat plate imager, using X ray digital imaging products of mainstream manufacturers at home and abroad.

The mechanical flexible electric device realizes the mechanical control of various translations, lifting and rotating of the front end equipment, and quickly completes the equipment location according to the requirements.

The control and graphics processing platform remotely controls the mechanical transmission and front-end equipment, and completes the equipment position control and X ray imaging control. Receiving the image information transmitted by the front end equipment, realizing intelligent analysis, defect recognition and detection report.

The equipment health status image data platform based on cloud technology is used to collect equipment life cycle Bureau and X ray image data, establish equipment health files, keep track and analysis of equipment status and change trend, so as to find equipment defects and hidden dangers more timely.

Technical advantages:

1. High detection efficiency

The detection mechanism of the mechanical transmission is provided, the location and the angle adjustment of the X ray machine and the imager are adjusted by the combination of the site placement and the remote tuning. The multi angle detection imaging of different parts of the electric power equipment is completed and the efficiency of the imaging detection is improved. At the same time, the monitoring device has been improved to the power equipment. The adaptability of the operation site.

One button realizes the imaging detection process of image control, image acquisition, image display, image processing, image storage and so on, and reduces labor intensity.

2. Rich data resources

It provides an integrated library of original drawings or models, X ray inspection images and equipment defect characteristics samples.

3, perfect data analysis

Based on the X ray inspection image, combined with other relevant data, defect diagnosis and visual location are carried out.

4. Powerful image processing

A series of image processing methods, such as image transformation, enhancement, edge detection, image restoration, image segmentation and image splicing, are provided to improve the relative quality of X - ray images so as to extract information effectively.

5. Extensive detection and application environment

scom X ray test is suitable for tension clamp, insulator, PT, GIS combination switch and cable line. In the light of the compact GIS equipment that ABB and SIEMENS and other international manufacturers have introduced in recent years, the company uses a unique detection technology to meet the detection requirements of various application scenarios, and ensures the reliability of the equipment in the safe use of electricity.