System background:

In recent years, the explosion of the switchgear has occurred frequently, and once it happens, it causes a very serious power grid accident. Many explosions are caused by the bad contact between the moving and static contacts of the internal circuit breakers. The electric power personnel often consider the reasons of the failure from the use of the service life, the installation process, the operation method and so on, and ignore the material problems. Electrical personnel in the new station or new switch cabinet detection of the lack of material testing equipment and means.

The contact part of the switch cabinet consists of the plum blossom touch head and the static contact. The contact surface of the contact surface is a detection blind spot. The switch manufacturer makes the contact part of the conductive contact on the surface of a silver plating. The silver has excellent conductivity to prevent the oxidation of the contact and improve the electrical conductivity.

The silver plating thickness of qualified thickness is the basic condition to ensure the contact resistance reaching the standard, which directly affects the reliability and operation life of the high voltage switch contacts. In addition, because the contacts of the switch equipment need to have "self cleaning" function, that is, the contact insertion and extraction of contact need to clean the surface through friction. In order to prevent the silver coating from overly thinning or peeling in the process of friction, the silver coating ensures its safety by ensuring a certain thickness.

Application status:

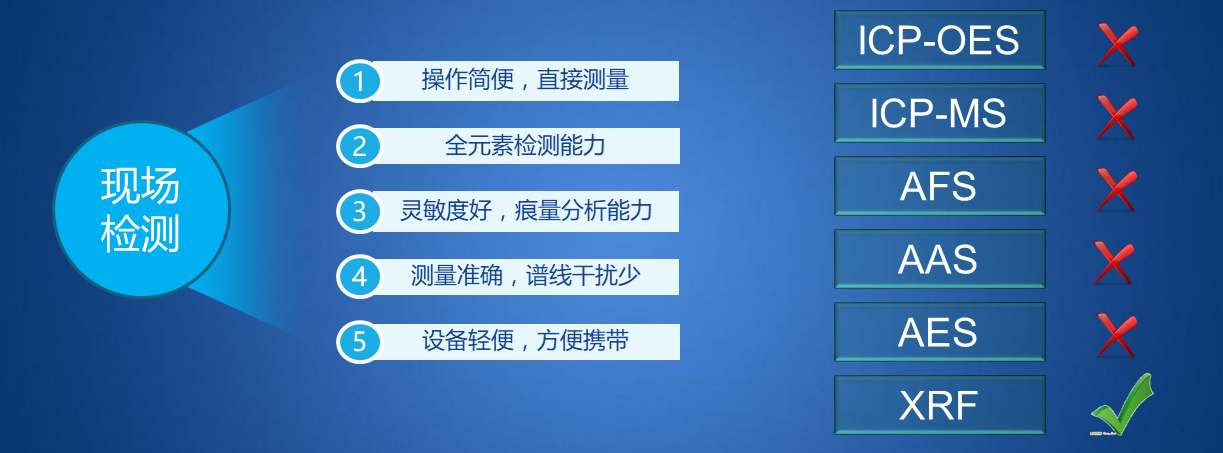

The XRF technology is the only detection technology that does not need complex sample pre processing, which really realizes the direct detection of solid samples.

Product type:

System performance:

1. The whole machine is reliable

A, the use of sealed anticollision plastic shell.

B,Strict sealing between B and plastic shell, good dustproof and waterproof.

2. Instrument stability

A, large area heat sink to improve the performance and stability in hot environment.

B and -10~+50 C can be used steadily.

3, full protection

A, instrument screen, nose cone and handle are filled with rubber shockproof to prevent impact during transportation.

B, configure special protective net to prevent detects when debris and irregular samples are detected.

4. The design of MiX5 handheld analyzer has passed IP54 authentication.

5, small volume, MiX5 is the most compact handheld XRF in the industry.

6, complete X ray protection

A, small proximity sensors, close to the analysis window, can ensure that the instrument can detect small samples safely and simply.

B, special small sample analysis X protective cover and instrument base.

C, maximum voltage and current setting, radiation leakage at any location is less than 1 Sv/h.

D, high brightness "X ray" warning light.