System background:

The high voltage switchgear, busbar connector, outdoor knife switch, transmission line wire and other important equipment in the substation and power plant. In the long run, the contact points of the switch and the busbar connection are overheated because of the excessive aging or contact resistance. The temperature of the heating parts, such as the real time monitoring of the fruit, will probably lead to the final guide. In order to prevent the occurrence of fire and large area blackout, the problem of overheating in the process of equipment operation is the key to prevent such accidents. Therefore, on-line monitoring of temperature is an important means to ensure the safe operation of high voltage equipment.

Solution:

Using the principle of surface acoustic wave temperature measurement, the temperature information is transformed into components of electromagnetic wave frequency signal. The temperature sensor is a temperature sensor installed directly on the surface of the measured object. It is responsible for receiving the radio frequency signal and returning the radio frequency signal with the temperature information to the collector. When the temperature sensor works normally, no external power supply is needed, such as battery and CT loop power collection mode. The signal transmission between the temperature sensor and the temperature collector is realized by wireless electromagnetic wave.

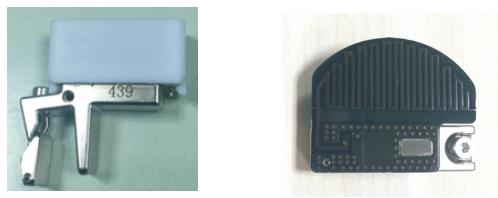

Temperature sensor

According to the different installation methods, the temperature sensor is divided into three types: the tuning fork sensor, the binding sensor and the self locking fastener sensor, which are suitable for different environments. According to the temperature range and installation position, it can be divided into ordinary and high temperature, corresponding to the temperature of the bus bar and the moving contact. The movable contact mounting sensor is fixed on the plum contact finger of the moving contact of the handcart cabinet.

Collector transceiver antenna

The transceiver antenna of the collector completes the signal transmission of the temperature collector and the temperature sensor for sending and receiving electromagnetic wave signals. Used with the temperature collector, it is installed in the same compartment of the sensor, and is responsible for communication with the sensor antenna to complete the sending and receiving of the excitation signal and the sensor signal.

Temperature collector

The temperature collector produces electromagnetic wave signals corresponding to the frequency point of the temperature sensor, and sends it to the temperature sensor, receives the electromagnetic wave signal with the temperature information returned by the temperature sensor, and parse the temperature signal to the station end temperature measurement management device. The downlink collectors communicate with a set of sensors, which are responsible for transmitting radio frequency pulses and processing sensor signals reflected by sensors, and finally resolve them into effective temperature information.

Cloud server for temperature measurement system

The data management of the temperature measuring system is completed by the monitoring software of the cloud server. The server receives the data sent by the temperature measuring device at the end of the station and realizes the remote automatic monitoring of temperature. It can automatically collect the temperature data of the subordinate station in the system and store it, and can provide the real-time temperature curve, temperature rise curve, historical temperature curve and so on. To achieve remote automatic alarm: provide temperature limit, temperature rise limit alarm mode, provide SMS, mobile terminal APP and other alarm modes.

Access to server data can be achieved through personal computers or mobile terminals, such as mobile phones.

Technical advantages:

1, passive wireless way to achieve high voltage isolation, no battery, high security.

2. The passive temperature sensor is small in volume and wireless in data transmission between the collector. It is easy and flexible to install and is not affected by the structure and space of the equipment.

3, sensors need not use batteries. After installation, there is no need for maintenance.

4, the temperature measuring device is not affected by environmental factors such as dust and electromagnetic fields, and it can work steadily for a long time.

5, the radio frequency signal has a certain penetrating diffraction ability, it can be widely used to measure the temperature of various objects in the visible range and obstacles.

6, the passive mode of operation is not limited by the power supply of the power supply. It can acquire the temperature information at higher frequency and has high real-time data.

7. It can be installed on the contact finger of the hand cabinet and directly collect the temperature of the user's most concerned position, and accurately reflect the running state of the equipment.

Product features:

Technical maturity

On the basis of cooperation with foreign manufacturers, a AW temperature measuring product developed independently has been formed to solve the technical defects of foreign products in the aspects of anti-interference, electromagnetic compatibility, transmission distance and stability.

technical standard

As the lead and the main compilation unit, it has participated in the formulation of the electric power industry standard "the technical specification for the on-line monitoring device for the contact temperature of the substation equipment".

Market and sales

It is the largest market share of SAW passive wireless temperature measurement in the domestic power industry.

application

Different application solutions have been formed for switchgear, distribution transformer, power cable, disconnector and so on. Two working modes of on-line temperature monitoring and inspection are formed.

technical support

It has a large number of excellent technicians who have long been engaged in the development, implementation and service of SAW technology and power industry monitoring devices. It has formed good cooperation with China Academy of electrical science, South power grid, and universities, providing strong technical support for product R & D and application.